Thermal insulating materials are determined by their respective R-values.

The R–value is a measure of an insulation’s ability to reduce the rate of heat flow under specified test conditions. The primary mode of heat transfer impeded by insulation is conduction, but insulation also reduces heat loss by all three heat transfer modes: conduction, convection, and radiation.

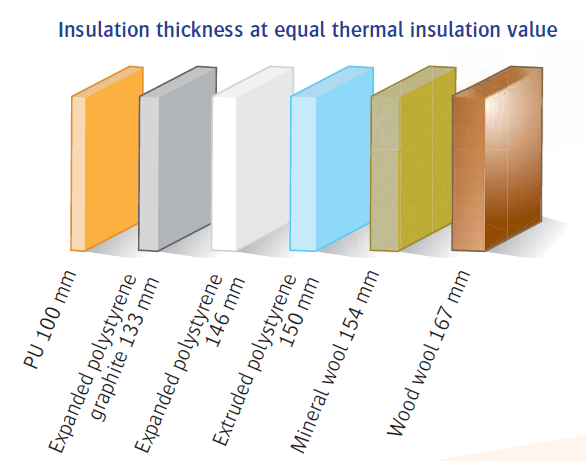

When it comes to choosing the right installation for your home, it is not the thickness of the product or the type of material that counts, but the R-value. The greater the R-value, the greater the resistance to heat transfer, and the greater the insulating effect and subsequent energy savings.

R-value is measured in m2.k/W per inch.

| Material | RSI-value (m2·K/W) | R-value (ft2·°F·h/BTU) | RSI-value (m·K/W) (per metre) |

| Vacuum insulated panel | 5.28–8.8 | 14–66[46] | 208–346 |

| Silica aerogel | 1.76 | 10.3[47] | 69 |

| Polyurethane rigid panel (CFC/HCFC expanded) initial | 1.23–1.41 | 7–8 | 48–56 |

| Polyurethane rigid panel (CFC/HCFC expanded) aged 5–10 years | 1.10 | 6.25 | 43 |

| Polyurethane rigid panel (pentane expanded) initial | 1.20 | 6.8 | 47 |

| Polyurethane rigid panel (pentane expanded) aged 5–10 years | 0.97 | 5.5 | 38 |

| Foil-faced Polyurethane rigid panel (pentane expanded) | 1.1–1.2 | 45–48 [48] | |

| Foil-faced polyisocyanurate rigid panel (pentane expanded) initial | 1.20 | 6.8 | 55 [48] |

| Foil-faced polyisocyanurate rigid panel (pentane expanded) aged 5–10 years | 0.97 | 5.5 | 38 |

| Polyisocyanurate spray foam | 0.76–1.46 | 4.3–8.3 | 30–57 |

| Closed-cell polyurethane spray foam | 0.97–1.14 | 5.5–6.5 | 38–45 |

| Phenolic spray foam | 0.85–1.23 | 4.8–7 | 33–48 |

| Thinsulate clothing insulation[49] | 0.28–0.51 | 1.6–2.9 | 11–20 |

| Urea-formaldehyde panels | 0.88–1.06 | 5–6 | 35–42 |

| Drywall[50] | 0.15 | .9 | 6.2 |

| Urea foam[51] | 0.92 | 5.25 | 36.4 |

| Extruded expanded polystyrene (XPS) high-density | 0.88–0.95 | 5–5.4 | 26–40[48] |

| Polystyrene board[51] | 0.88 | 5.00 | 35 |

| Phenolic rigid panel | 0.70–0.88 | 4–5 | 28–35 |

| Urea-formaldehyde foam | 0.70–0.81 | 4–4.6 | 28–32 |

| High-density fiberglass batts | 0.63–0.88 | 3.6–5 | 25–35 |

| Extruded expanded polystyrene (XPS) low-density | 0.63–0.82 | 3.6–4.7 | 25–32 |

| Icynene loose-fill (pour fill)[52] | 0.70 | 4 | 28 |

| Molded expanded polystyrene (EPS) high-density | 0.70 | 4.2 | 22–32[48] |

| Home Foam[53] | 0.69 | 3.9 | 27.0 |

| Rice hulls[54] | 0.50 | 3.0 | 24 |

| Fiberglass batts[55] | 0.55–0.76 | 3.1–4.3 | 22–30 |

| Cotton batts (Blue Jean insulation)[56][57] | 0.65 | 3.7 | 26 |

Vitapur offers Polyurethane rigid panels, which rank third for thermal insulation according to the R-value table.

Also, we have Foil-faced polyurethane rigid panels, Foil-faced polyisocyanurate rigid panel, Closed-cell spray foam, and Polyisocyanurate rigid foam. All these insulating materials are ranked between 3 through 11 on the R-value table.

You can also contact us for your Polyethylene insulation needs; the R-value of Polyethylene is 0.52 m2.k/WKindly visit www.vitapurinsulation.com for more information or engage us on our social media platforms.